Relentless Pursuit of Innovation

At Wuzheng Group, innovation drives everything we do. Guided by a user-centric philosophy, we develop high-quality products to meet the evolving needs of our customers. Our goal is to enhance productivity while focusing on cost efficiency and environmental sustainability. Each year, we dedicate over 5% of our revenue to research and development, creating new productivity standards that resonate across the Wuzheng ecosystem.

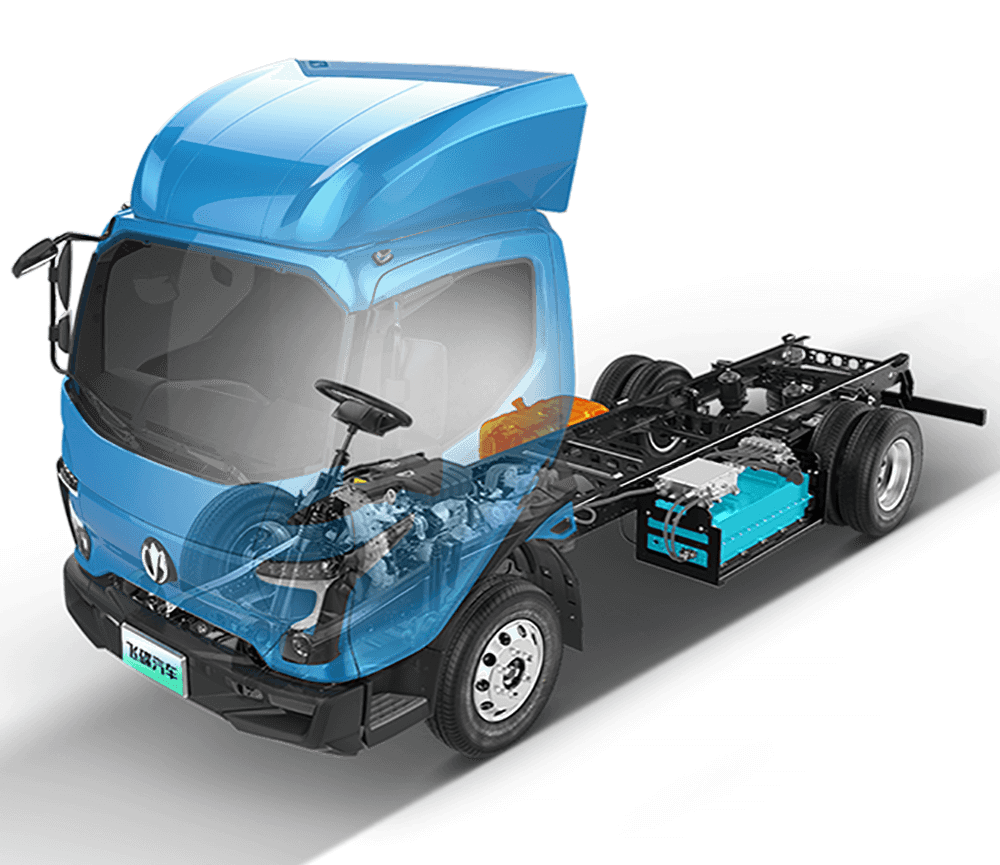

Reducing Fuel Costs for Mountainous Regions:

Designed for regions with steep slopes and winding roads, Wuzheng HW5 hybrid vehicle utilizes an advanced hybrid system that reduces fuel consumption by over 25%. Intelligent technologies assess the vehicle's load and road gradient, supplementing real-time engine power as needed to enhance efficiency.

Intelligent Technology for Comfort and Performance:

Equipped with a programmable clutch for smooth take-offs on steep terrain, ensuring responsive performance and further minimizing fuel consumption. These innovations empower HW5 to excel in mountainous environments, significantly cutting operating costs.

Enhanced Durability through Structural Optimization:

Wuzheng silage machinery incorporates advanced particle dynamics and CFD simulations for multi-physics coupling analysis. The optimized design reduces the pressure of particles on the wall of the throwing cylinder by 33.6%, extending equipment lifespan and cutting maintenance costs.

Increased Efficiency and Reduced Waste:

The improved throwing mechanism boosts particle velocity by 17.8%, allowing the equipment to process up to 30 tons of silage per hour with a 95% crushing rate. This minimizes waste and ensures safe, reliable operations for our users.

Improved Safety in Particle Collection:

To further enhance safety and user experience, we optimized the particle collection process, allowing collection trucks to operate at a safer distance from the silage machine. This ensures smooth particle transfer, minimizing potential hazards and improving user confidence in the field.

These innovations reduce downtime and maintenance costs, enabling our users to perform tasks more efficiently and safely, ultimately driving higher profitability and operational success.

Core Competency in Autonomous Driving:

Wuzheng's proprietary L4-level low-speed automatic driving sharing platform integrates cutting-edge positioning, perception, decision-making and planning, and vehicle control technologies. Our autonomous chassis solutions have been deployed in industrial parks, delivering significant cost savings—up to 80,000 RMB per vehicle annually—while improving logistics efficiency.

Future-Ready Solutions:

We are committed to advancing autonomous technology through comprehensive solutions, including remote driving systems, V2X roadside solutions, and cloud-based control platforms. Our goal is to enable seamless unmanned logistics for industrial environments, empowering customers to focus on core business operations.

Comprehensive Digital Solutions:

The Wuzheng Industrial Internet Platform spans multiple sectors, including agricultural vehicle telematics, fuel vehicle telematics, and smart sanitation operations. This platform supports Wuzheng's complete digital transformation by offering seamless, one-stop services to users.

End-to-End Business Management:

With our platform, users can efficiently manage operations from anywhere. Whether scheduling team tasks, conducting remote diagnostics, controlling vehicles, or managing financial locks, customers have complete access to all relevant information with just a few clicks.

Efficient Operations at Your Fingertips:

With user-friendly apps like Feidi Worm Hole, Feidi Leasing, Wuzheng Cloud Service and Wuzheng Smart Choice, customers can easily access spare parts, maintenance, and emergency services with just a few taps. These digital tools enhance convenience and deliver a superior user experience.

Optimized Business Operations:

With integrated platforms for digital R&D, digital marketing, and more, the Wuzheng Industrial Internet Platform boosts operational efficiency. It enables businesses to adopt more scientific, transparent management practices, ensuring streamlined and effective workflows.

In collaboration with Michelin, Wuzheng Group is committed to developing eco-friendly tractor tires, supporting sustainable agriculture with the philosophy that "Green mountains and clear waters are as valuable as gold".

Soil Structure Protection:

The ultra-low pressure radial tires increase contact area, reducing soil compaction and preserving soil health. This ensures long-term agricultural productivity and sustainability.

Enhanced Performance:

The tires offer superior enhance braking and maneuverability, delivering a quieter and more comfortable driving experience.

Lower Fuel Consumption:

By reducing soil compaction, the tires lower fuel consumption and carbon emissions, contributing to sustainable farming practices and cost savings.

Proven Reliability:

In a joint 2020 field study with Michelin, we validated safety and performance of these tires in diverse agricultural applications, demonstrating tangible environmental and financial value for farmers.

Optimizing Farm Efficiency

Patnering with Huawei, Wuzheng developed a dynamic healh management system for livestock, enabing precise growth tracking to optimize feeduilization and nutritionmanagement, thereby saving costs.

Hands-Free and Scientific Management

Auomated weighing svstem minimizes ivestock stess ensuing bealhier growth and streamlinino feeding processes This scienifc approachensures effcient livestock management and enhanced proftability.

Fully Visualized Farm Management

Our solfion provides fiul visualization of famm operaions, facilitating remote management and infommed data-diven decisions to erhance productivihand reducina operational costs.

Wuzheng Harvesting Machinery Team has developed an innovative integrated harvesting and baling system that combines these two processes into a seamless operation. This technology enables direct cutting and sealing of crops such as corn and other green plants, ensuring efficient and streamlined workflows.

Nutrient Preservation:

Our innovative harvest-and-baling system ensures rapid forage sealing in just three minutes, maximizing nutrient retention and delivering high-quality feed for livestock.

Streamlined Operations:

The integrated system eliminates multiple steps in traditional silage preparation, improving efficiency and simplifying operations.

Safe and Reliable Process:

This one-step system minimizes oxidation and contamination risks, ensuring the delivery of nutritious, safe feed to support livestock health.

Wuzheng Harvesting Machinery Team has developed an innovative system that combines the harvesting and shredding processes into a single operation. This technology enables the direct cutting and shredding of desert shrubs like caragana korshinskii, transforming them into high-quality commercial feed on-site.

Cost-Effective Operations:

By integrating harvesting and shredding, our solution reduces processing costs by 50%, making the large-scale use of desert plants for feed production both practical and affordable.

High-Quality Feed Production:

The innovative process preserves the high protein content of shrubs, delivering nutrient-rich feed directly from the field.

Ecological Conservation:

By leveraging caragana's natural ability to stabilize soil and prevent erosion, Wuzheng technology promotes sustainable agricultural practices.

Simplified Workflow:

By integrating the harvesting and shredding steps, our system streamlines traditional processes, saving time and labor. The simplified operation allows users to complete tasks more efficiently, improving overall productivity.

Nimble Solutions for Complex Terrain:

Wuzheng's compact three-wheel vehicles excel in challenging terrains, streamlining tasks like fertilizing, spraying, and pest control.

Multi-Functional Applications:

Our versatile machine can spread granular fertilizers, bio-fertilizers, and seeds, making it ideal for orchards, greenhouses, and small farms.

Cost-Effective Operations:

By replacing traditional manual fertilization, our vehicles improve efficiency, reduce waste, and minimize environmental impact. Their low-cost operation ensures a fast return on investment, driving early profitability for users.

Health and Environmental Benefits:

By minimizing workers' exposure to hazardous environments, Wuzheng's solution enhances occupational safety and promotes healthier working conditions. This eco-friendly approach supports sustainable farming practices, contributing to long-term environmental stewardship.

In 2022, Wuzheng launched its proprietary Easy-Drive System, designed to enhance the usability of all Wuzheng tractors. This advanced system streamlines tractor operations through one-touch controls for key functions.

Improved Comfort and Reduced Fatigue:

The Easy-Drive System features electronic lift, hydraulic output, and PTO controls, making tractor operation smooth and effortless. This reduces physical strain and fatigue, enabling operators to work comfortably for extended periods.

Boosted Work Efficiency:

The one-touch control simplifies the complex steps involved in lifting and turnaround operations, enhancing overall productivity.

Time-Saving Solutions:

Users experience over 20% faster turnaround times, optimizing productivity during plowing and other field operations.

Wuzheng's specialized equipment revolutionizes the cleaning process for coal transportation. This innovative solution improves both worker safety and environmental performance.

Health and Safety:

The equipment eliminates workers' exposure to hazardous coal dust, significantly reducing the risks of occupational diseases and injuries. This ensures better protection for workers' health and promotes safer working conditions.

Environmental Sustainability:

Our equipment minimizes airborne coal dust, contributing to improved air quality and fostering sustainable environmental practices. This innovation aligns with our commitment to reducing pollution and enhancing the well-being of surrounding communities.

Enhanced Operational Efficiency:

Tasks that previously required 20 workers in 40 minutes can now be completed by two operators in just 30 minutes, significantly reducing labor and time costs while ensuring safer working conditions, leading to more efficient operations, enabling businesses to optimize productivity and resource allocation.

The next step

Please feel free to reach us to discover more opportunities together!