Located in the Northern Economic Development Zone of Rizhao City, the FEIDI Vehicle Manufacturing Facility spans 1,300 acres, with a factory area covering 220,000 square meters. The facility houses five core workshops: Stamping, Welding, Chassis, Coating, and Final Assembly, alongside key component production areas, including vehicle testing, drive axles, cargo boxes, and wiring harnesses. With an annual production capacity of 100,000 vehicle sets, we leverage cutting-edge technologies to meet the rigorous demands of the global commercial vehicle market.

-

1300acres

Area covered

-

220000m²

Factory area

-

100000units

Annual production capacity

-

Manufacturing Workshop

Manufacturing Workshop -

R&D Center

R&D Center -

Three coordinate detection room

Three coordinate detection room -

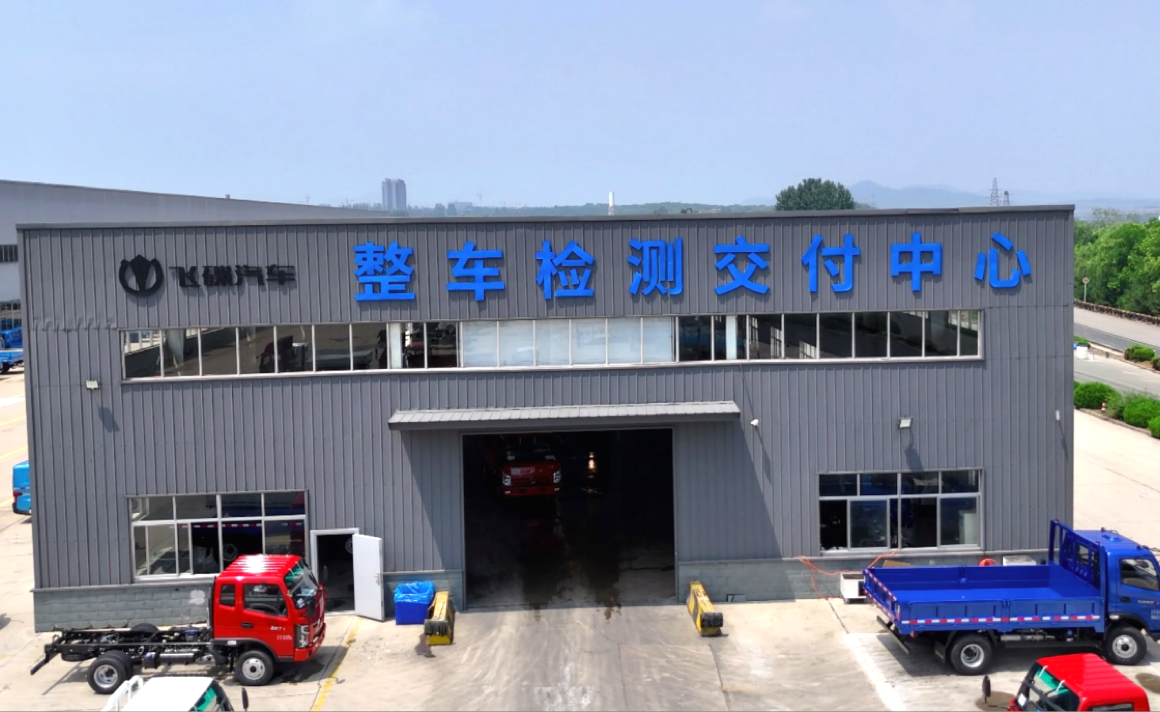

Whole Vehicle

Whole Vehicle

At FEIDI, our manufacturing philosophy prioritizes customer needs, satisfaction, safety, and environmental sustainability. By driving continuous innovation and optimizing production processes, we deliver high-performance, high-quality vehicles while upholding the principles of zero injury, zero defect, and zero waste across all stages of manufacturing.

Five Core Workshops

Our five core workshops are equipped with fully automated, precision-engineered machinery to ensure structural integrity and reliability in every vehicle we produce. Automation underpins consistent quality, efficiency, and durability, meeting global standards.

-

Stamping

Stamping -

Welding

Welding -

Chassis

Chassis -

Coating

Coating -

Final Assembly

Final Assembly

The stamping workshop features three high-efficiency automated lines with a total capacity of 12,000 tons. These precision systems achieve deep drawing of side panels in a single stroke, ensuring robust part formation and superior structural strength. With a production rate of four parts per minute, we enhance operational efficiency while maintaining cost-effectiveness. Our lean manufacturing processes, alongside a comprehensive quality management system, ensure outstanding results for all FEIDI commercial vehicle body stampings.

Equipped with 59 internationally recognized ABB robots, the welding workshop integrates visual assembly systems and EMS automation for tasks such as handling, gluing, welding, and components transfer. Automated online dimension monitoring system and advanced welding process controls maintain a tight tolerance of ±1.0mm, ensuring consistent product quality and durability throughout the manufacturing process.

Intelligent Control for the Future, Safety on the Road — The chassis workshop utilizes high-precision laser cutting machines and 6300T presses, employing 510L high-strength large beam steel and precision riveting jigs to achieve millimeter-level precision in chassis assembly. The solid steel frame structure guarantees superior safety and reliability for every vehicle, providing a secure and smooth driving experience.

Our coating workshop employs internationally recognized electrophoresis pre-treatment materials for superior corrosion resistance, extending vehicle lifespan and maintaining a premium appearance. With nine robotic spray units and advanced coating process controls, including paint formulation and spray parameters, we achieve uniform exterior finishes, enhancing both durability and aesthetic appeal.

Equipped with intelligent technologies such as automated code-scanning systems, liquid filling error-proofing, ANDON systems, and multi-axis tightening machines, the final assembly line ensures meticulous control over key components, preserving the consistency and stability of every completed vehicle.

Testing Center

FEIDI’s Testing Center incorporates advanced quality control systems, including 3D coordinate measurement, VAS (Vehicle Assessment System), a whole vehicle review center, and a dedicated coating laboratory, all ensuring rigorous quality control and validation at every stage of production.

The Three-Coordinate Measurement Room is equipped with both cantilever and portable coordinate measuring devices capable of high-precision measurements for body-in-white, components, and fixtures, ensuring the size and shape accuracy of parts. The portable systems mobilize real-time quality monitoring across various workshops, driving continuous quality control and improvement. The equipment is supported by specialized software for real-time measurement data analyzing and processing, ensuring traceability and continuous improvement in line with design specifications.

The Vehicle Assessment System is a user-centered platform that simulates real-world usage scenarios to deliver consistent, objective quality metrics and assessments aligned with FEIDI’s stringent manufacturing standards. Dynamic testing is conducted to measure and analyze various vehicle performance indicators, ensuring product competitiveness and performance.

The Whole Vehicle Review Center integrates five key modules: offline inspection, testing line, appearance evaluation, rain tests, and dynamic assessments, realizing the standardized and streamlined vehicle inspection and delivery center. The comprehensive and multi-dimensional evaluation of vehicle performance and quality guarantees high-quality products off the line.

The coating laboratory, with an investment exceeding one million RMB, is a standardized facility that implements parametric management. Equipped with advanced testing equipment and techniques for comprehensive analysis of coating quality, it delivers critical support for overall quality control and consistent coating performance.

The next step

Please feel free to reach us to discover more opportunities together!